European Standarts for Machines

EUROPEAN STANDARDS FOR MACHINES

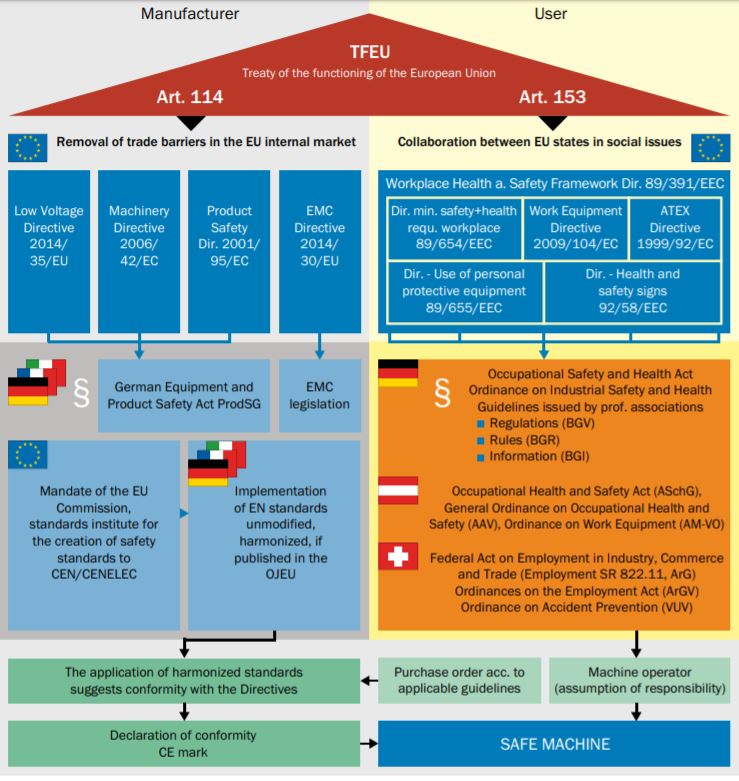

One of the main ideas of the European Community is to protect the health of its citizens both in their private and business life. Another basic idea is to create a uniform market with free goods circulation. In order to achieve the objectives of free movement of goods and citizens’ protection at the same time, the EU Commission and the Council of the European Union have issued various directives. These will be included in national laws by the member states. The directives define the main objectives and conditions and the technology is kept as objective as possible.

The following directives have been adopted in the field of machine safety and occupational safety:

- Machinery Directive for machine manufacturers,

- Operating Equipment Use Directive for machine operators,

- Additional directives, eg Low Voltage Directive, EMC Directive, ATEX Directive

As can be seen from the table above, it is necessary to meet the EU directives for the CE declaration of conformity. The simplest way to meet the directives is to comply with the harmonized relevant European standards. This means that you do not have to comply with the harmonized standards for manufacturing in accordance with the CE declaration of conformity and the European standards, but you have to identify and prove a method to produce in accordance with the directives. When you produce according to harmonized standards, it is accepted that you comply with the directives and it is the easiest and practical way to comply with the standards instead of developing a new method.

European Standards on Machine Safety

In order for the objectives and conditions specified in the European Directives to be applied in one form in practice, the technical standards should describe and embody these conditions in detail.

The status of the standard is indicated by various abbreviations:

- A standard bearing the EN is adopted and applicable in all EU countries.

- A standard bearing prEN is in preparation.

- A standard bearing the HD phrase has the same characteristics as EN, but the harmonization at the national level is different (Harmonization Certificate).

- In addition, a document bearing the TS phrase is the technical specification and is considered as the pre-standard. These documents are available as CLC / TS or CEN / TS.

- In addition, a document bearing TR is a report on excellence.

|

Summary: Laws, Directives, Standards What you need to do as a machine manufacturer according to the Machinery Directive, among others:

As a machine user, you should do as per the Working Equipment Directive:

Standards

|

EN954-1, EN13849, IEC 61508?

In this section, we will give a short look at the safety standards of the machines we produce and try to explain the relationship between them. When the machines are called Security, the following standards come first.

EN954-1 – (Safety-related parts of safety-control systems in machines – Part 1: General rules for design)

This standard is replaced by EN13849-1, which came into force on 1 January 2012. EN13849-1 refers to this standard EN13849-1 on control methods.

EN13849 – (EN954-1) safety-related control systems of machinery replacing standard (software and hardware)

It has been in effect since 1 January 2012 and is being used instead of EN954-1. In EN954-1, only safety categories and structures are specified, while EN13849-1 more systematically includes safety, fault finding, structure, durability and process.

IEC 61508 – (Programmable electronic units that are used for safety in machines must comply with the standard) Functional Safety of Electrical / Electronic / Electronic Systems (E / E / PE, or E / E / PES)

If you have an electronic system or device which can be programmed in your system, this standard sets the required functional safety rules.

|

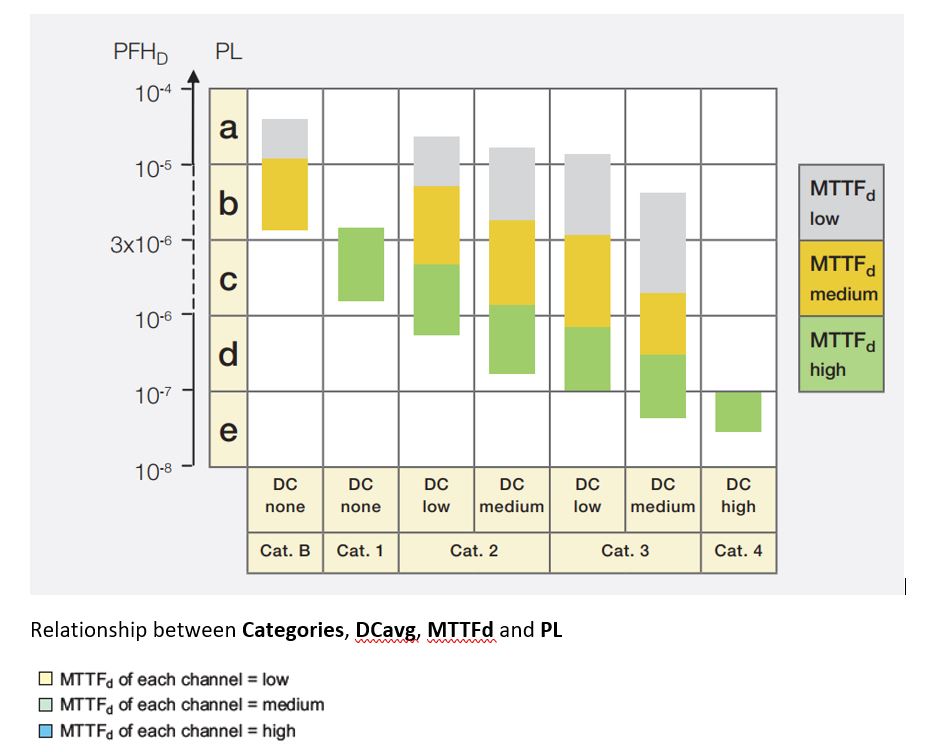

Denotation of each channel |

Range of each channel |

|

Low |

3 years ≤ MTTFd< 10 years |

|

Medium |

10 years ≤ MTTFd< 30 years |

|

High |

30 years ≤ MTTFd< 100 years |

Healthy working time (MTTFd) until each section is dangerous

Diagnosis (Diagnostics);

This parameter that measures error detection is called DC (fault detection scope). This parameter indicates the ability of the system to find errors.

DC = detected dangerous error rate (dd) / total dangerous error rate (dd + du)

|

Denotation |

Range |

|

None |

DC < 60% |

|

Low |

60%≤ DC < 90% |

|

Medium |

90%≤ DC < 99% |

|

High |

99%≤ DC |

Diagnostic Coverage (DC)

Structure;

On which structure you present the safety driver.

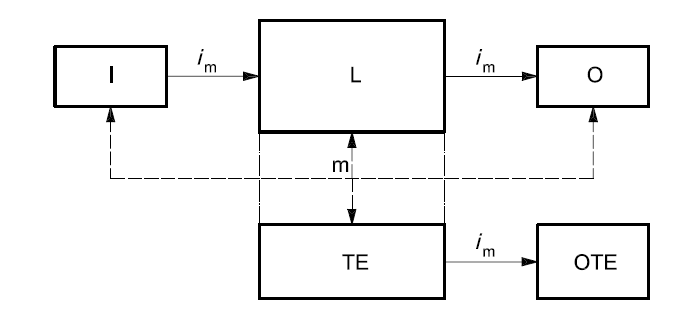

Example: Structure for Category 2 according to EN13849-1:

İm (interconnecting means)

C (cross monitoring)

I (input device, e.g. sensor)

L (logic)

m (monitoring)

O (Output device,e.g. main contactor)

TE (Test Equipment)

OTE (Output of TE)

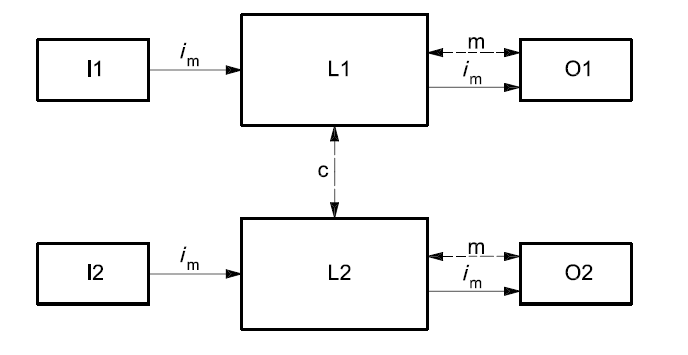

Example: Structure for Category 3 according to EN13849-1:

İm (interconnecting means)

C (cross monitoring)

I1,I2 (input device, e.g. sensor)

L1,L2 (logic)

m (monitoring)

O1,O2 (Output device,e.g. main contactor)

Sturdiness;

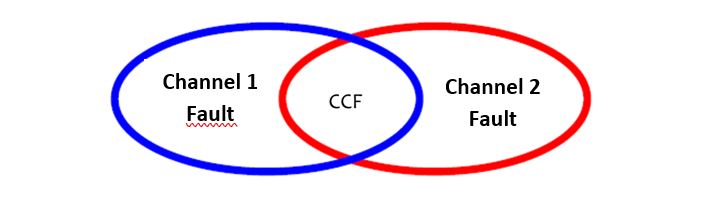

The parameter measuring resilience is called CCF (Common Cause Failure).

This parameter refers to the independence of the system channels for common cause failures. (Compulsory)

Verification and Validation process

It is very important to document and prove the entire process by defining PL and other parameters.

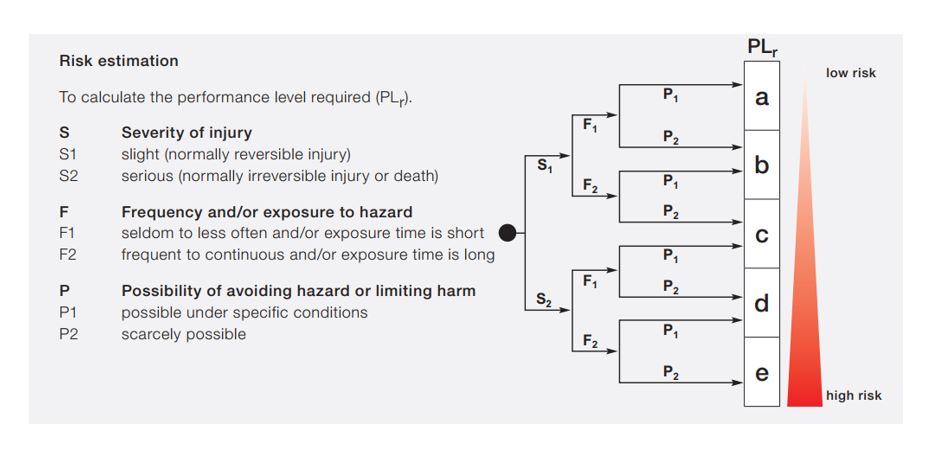

PL DETERMINATION

The manufacturer shall carry out a risk analysis for all functions of the machine and shall determine the system and method to be used in accordance with this risk analysis. The fact that all of the parts of the system have the same PL level does not mean that the entire system is at the same PL level. For example, PLd has created a system with a processor and PLd sensors. All of this system is not called PLd. A complete analysis and risk assessment should be performed and the PL level should be proved for the system.